Single Channel Heat Exchangers

Temperature Stability: ±0.1℃

Temperature Range: 25℃~+200˚C

Heating Capacity: 8 KW-200KW

Advanced PLC control with PID algorithms achieves ±0.1℃ precision temperature regulation of process fluid. This system is deployed across critical thermal management scenarios:

Semiconductor manufacturing equipment

New energy testing platforms

Medical diagnostic devices

Industrial laser systems

- Overview

- Recommended Products

Technical Description

Lingheng dual-circuit heat exchangers feature a 7-inch HMI touchscreen with intuitive Chinese interface, enabling clear parameter visualization, traceable fault logs (5000+ records), and real-time temperature trend monitoring for streamlined workflow management. The fully customizable UI supports industry-specific layouts, while the integrated RS485 port with Modbus-RTU protocol (IEC 61158-5 compliant) transmits 18+ critical data points including outlet fluid temperature (±0.1℃ accuracy), equipment fault codes, flow rates,and system status alerts to SCADA/MES systems.

Key Advantages

→ Compressor-Free Operation: Achieves rapid thermal response (<30s) without rotating parts

→ 8-Circuit Design: 80% space reduction vs. conventional units

→ High-Efficiency Plate HX: ±10°C/min temperature ramp rate

→ Remote Purge Kit (Optional): In-situ pipeline cleaning without disassembly

→ Multi-Protocol Integration: Pre-loaded SEMI SECS/GEM, OPC UA, PROFINET

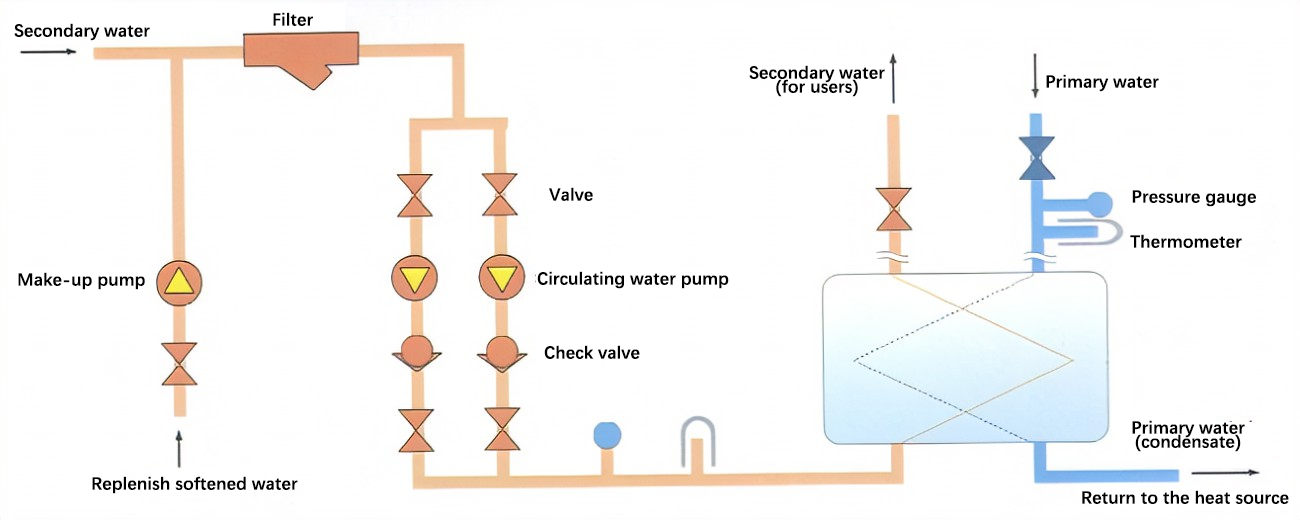

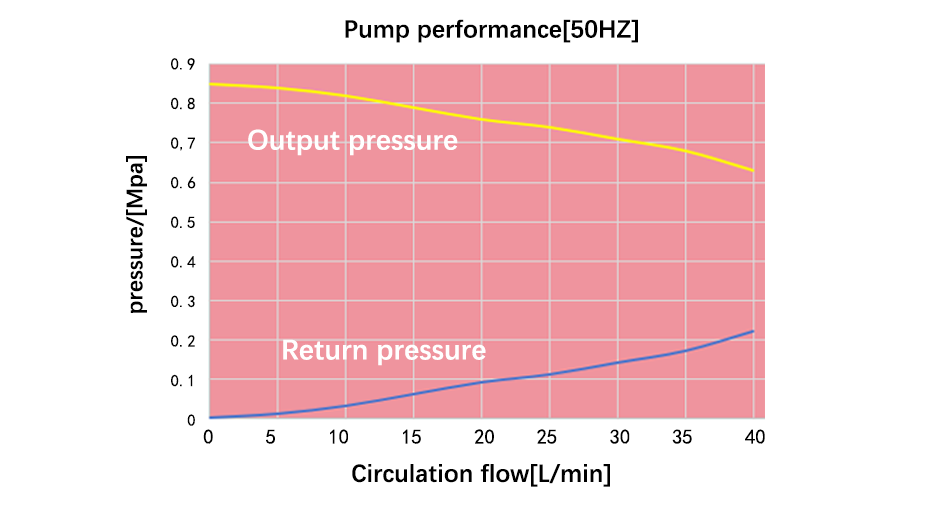

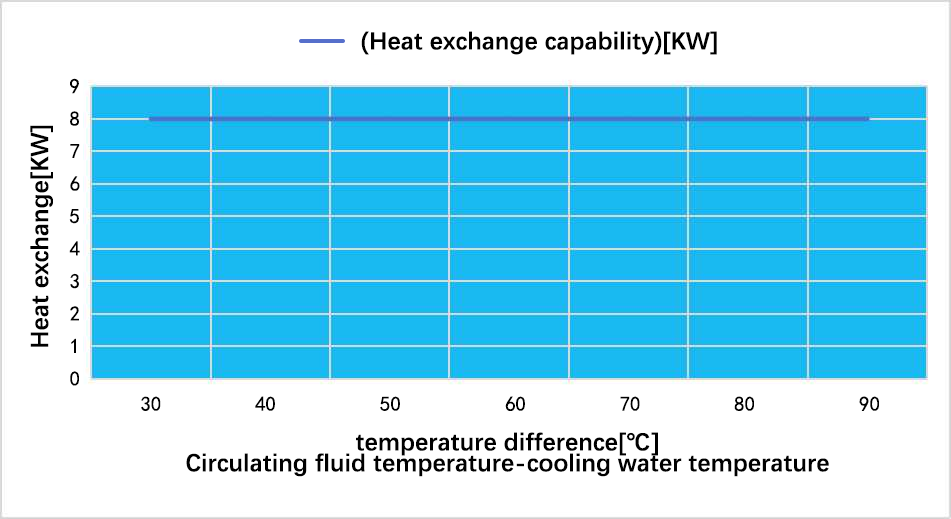

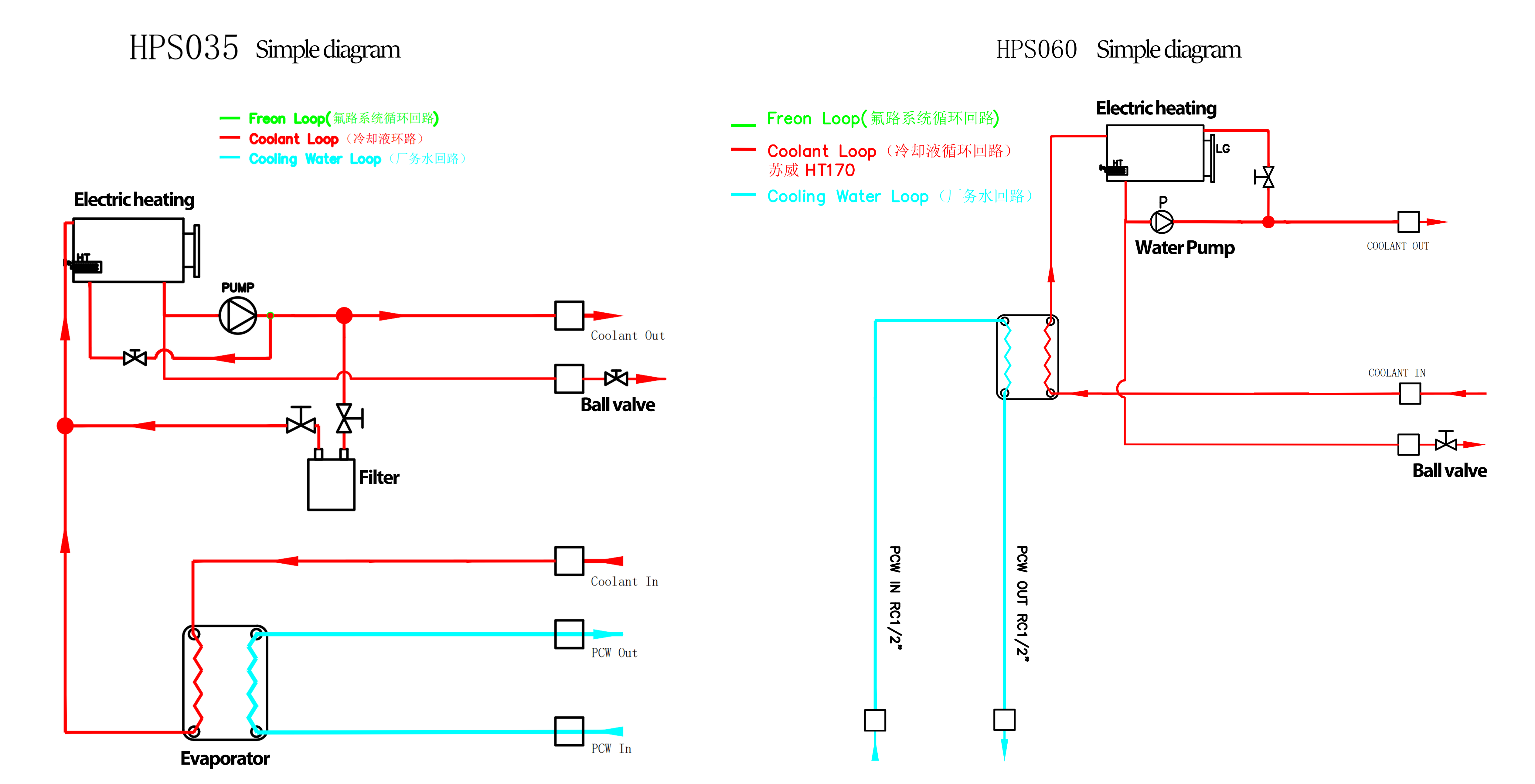

This single-circuit heat exchanger delivers precise temperature control from 30°C to 80°C (±0.5°C stability) with a maximum heat transfer capacity of 8kW at ΔT=10K. Operating within ambient temperatures of 5-35°C, its adaptive PID algorithm ensures exceptional thermal stability. The system incorporates a high-efficiency plate heat exchanger featuring vortex-optimized flow channels that achieve 35% greater heat transfer efficiency than conventional designs, making it ideal for battery formation (45±0.5°C cell temperature control), plastic molding (cycle time reduction >15%), and pharmaceutical processes compliant with USP <1079> standards.

Core Components & Operation

Characteristic |

Plate Heat Exchanger |

Shell-and-Tube Heat Exchanger |

Heat Transfer Driving Force |

High ΔT gradient + intense turbulence |

Primarily relies on temperature difference |

Flow Path |

Multi-channel parallel flow |

Single-path serpentine flow |

Fouling Impact |

Low fouling resistance |

Prone to scaling |

Temperature Response |

Second-level regulation |

Minute-level response |

| HPS008/120/040/200M Product Parameters | ||||

| Product | Heat Exchange HPS008 | Heat Exchange HPS120 | Heat Exchange HPS040 | Heat Exchange HPS200M |

| Product model | HPS080-W-32W | HPS120-W-32F2 / W-32F3 | HPS040-W-32W | HPS200M-W-33 |

| Cooling method | Water Cooled Heat Exchange Type | Water-cooling | ||

| Control mode | PID Control | |||

| Temperature Control Range | +30℃~+80℃ | 30℃~140℃ / 30℃~200℃ | +30℃~+80℃ | +20℃~+50℃ |

| precision | ±0.1℃ | |||

| Heat exchange | 8kW | 12 KW@PCW+10˚C | 40 KW | 30℃@200KW |

| Power | 3 KW x 2 | 3 KW x 6=18 KW | 3 KW x 2 | / |

| Tank | 20L | 25 L | 340L | |

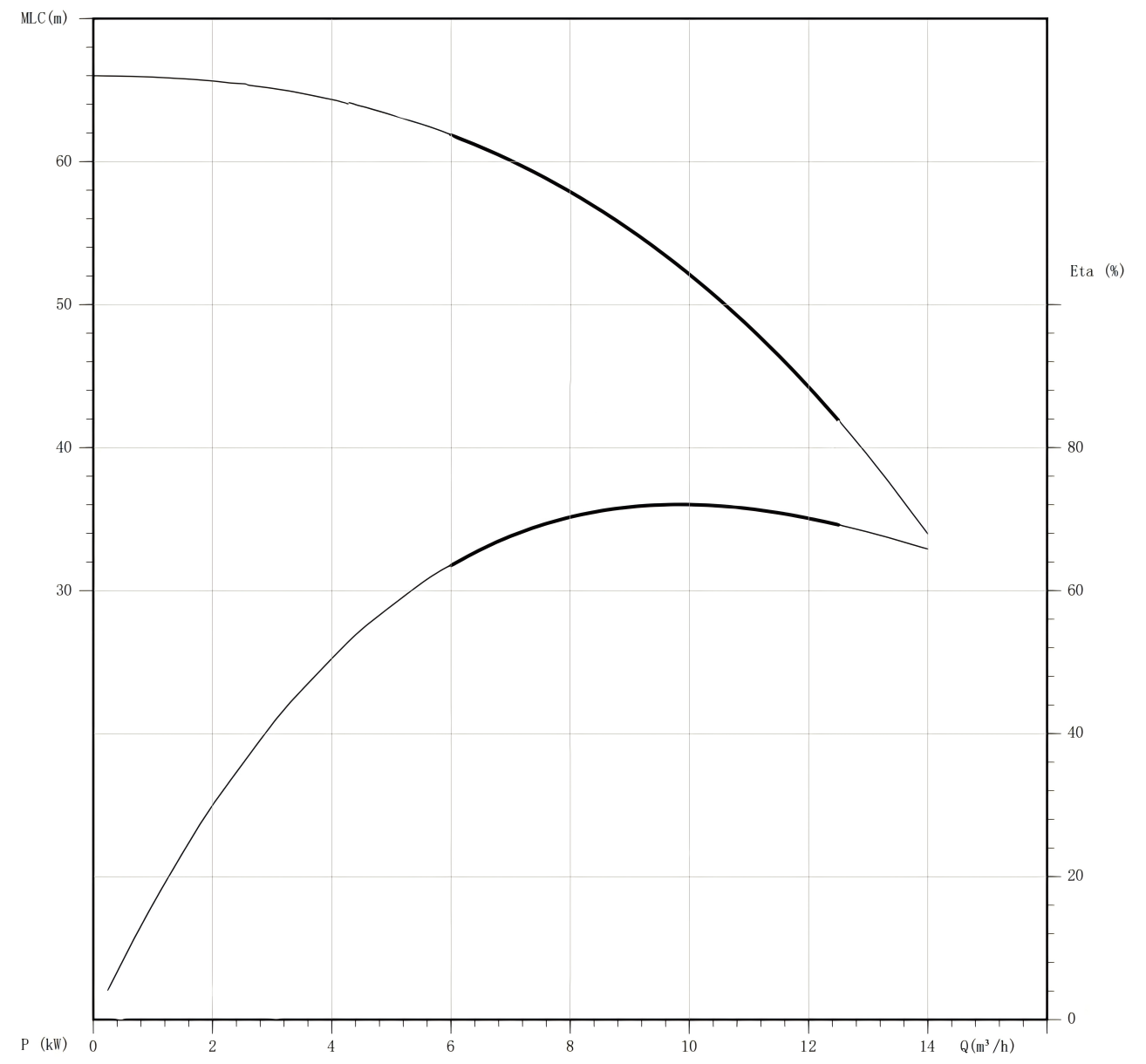

| Circulating liquid flow rate | 20L/min(0.65MPa) | 20L/[email protected] | 100 L/min | 160L/[email protected] |

| PCW traffic | 15L/min@15~25℃ | 80L/min@15~25℃ | / | |

| Temperature range | 5~35 ℃ | |||

| Types of circulating fluid | Ethylene glycol mixture, pure water/ DI Water | Fluorinated Liquid | Ethylene Glycol Mixture /DI Water | Ethylene glycol mixture, pure water |

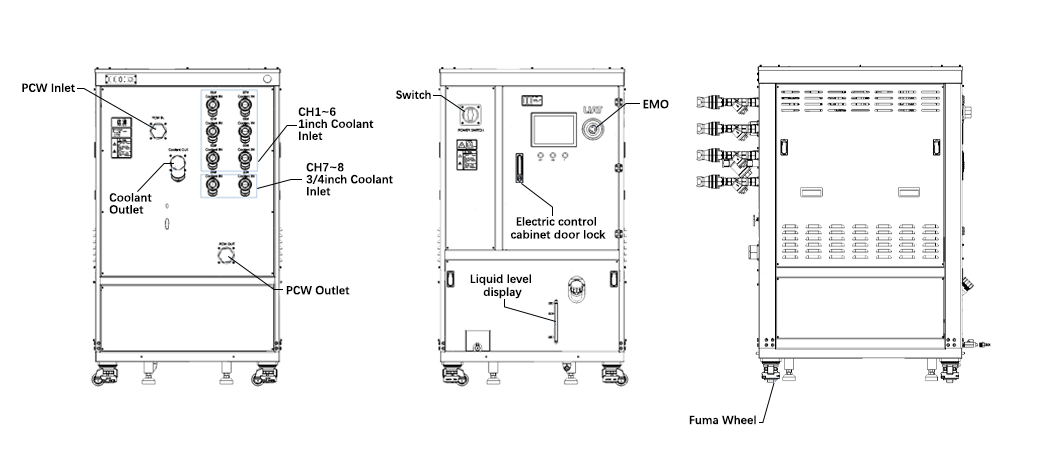

| Circulating liquid interface | Rc3/4“ | Rc 3/4" * 4 | Liquid outlet2”Liquid inlet1”*6+3/4“*2 | |

| PCW interface | Rc 1/2” | Rc 1” | RC2” | |

| External dimensions(mm) | 380W*900D*1300H | 520W*780D*1300H | 900W*1000D*1600H | |

| Input power supply | 3Ph,208-220V,50Hz | 3Ph, 380V,50Hz | ||

| Whole machine power | 7.6kW | 7~20 KW | 11 KW | 2.2 KW |

| Net weight | 180kg | 200 kg | 230 kg | 440 kg |

| Design standards | SEMI | |||