Triple Channel Chiller

Temperature Stability: ±0.1℃

Temperature Range: -40˚C~+80˚C

Cooling Capacity: -40℃@6 KW/20℃@25 KW

Industrial-grade compressor chiller featuring premium-brand compressors for exceptional stability. Delivers ±0.1℃ outlet temperature stability for critical applications including:

Photolithography/etching equipment cooling

PVD/CVD tool thermal management

Chemical & pharmaceutical reactor temperature control

GMP-compliant pharmaceutical process cooling

- Overview

- Recommended Products

Technical Description:

Lingheng Triple-Circuit Chillers deliver multi-load precision cooling (±0.1℃) in a single unit. Featuring configurable outputs for stable environments, they provide:

✅ Smart Control: Scheduled operation, auto-compensation, self-diagnostics

✅ Triple Safety: Overheat/overload/water shortage alarms

✅ Industrial Connectivity: I/O, RS232/RS485, Ethernet/IP

Engineered for semiconductor cluster tools and PV production lines with 30% energy savings.

Key Advantages:

TripleSync™ Integration

» 3 independent circuits in single chassis

→ 55% cleanroom footprint reduction

Cluster-Grade Precision

» ±0.1℃ stability with <±0.03℃ inter-circuit gradient

→ Enables multi-chamber process synchronization

Dynamic Load Balancing

» Smart cooling allocation (30kW total capacity)

→ 28% energy savings on variable loads

Multi-Tool Compatibility

» Plug-and-play with ASML/AMAT/TEL cluster tools

→ Supports 300mm fabs & PV TOPCon lines

Ultraclean Titanium Ecosystem

» Customizable flow paths with modular sealing

→ <0.1ppb fluid residue (Class 10 compliant)

Core Components & Operation:

Component |

Technology |

Compressor |

Hermetic inverter compressor with liquid slugging protection (±0.1℃ control) |

Condenser |

Stainless steel, <5% thermal loss |

Evaporator |

Plate-type design, 35% higher efficiency, ≤55dB noise |

Heater |

Submerged direct-heating, ±0.3℃ uniformity |

Expansion Valve |

Electronic valve with ±1℃ superheat control |

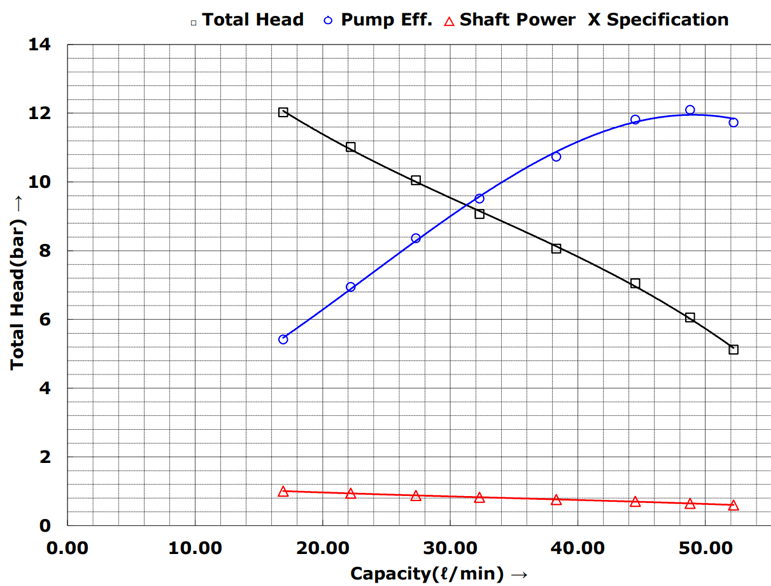

Pump |

Mag-drive pump (fluorinated fluid version), <2% flow fluctuation |

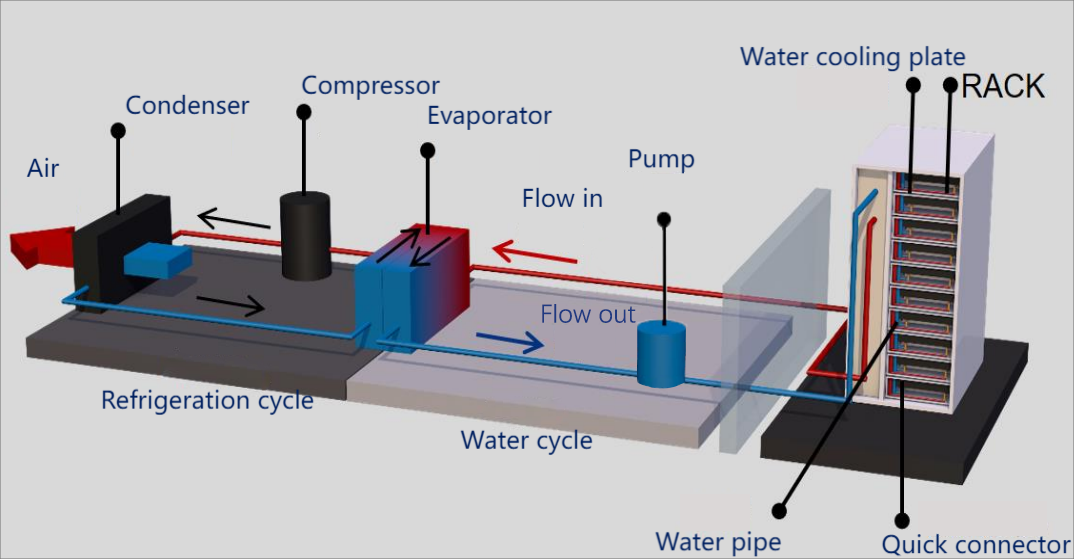

Refrigeration Principle:

Adaptive PID Refrigeration Cycle:

1️⃣ Compression → Refrigerant pressurization

2️⃣ Condensation → Heat dissipation & liquefaction

3️⃣ EEV throttling → Low-pressure generation

4️⃣ Evaporation → Precision heat absorption from equipment

5️⃣ Inverter flow control → Maintains ±0.1℃ stability

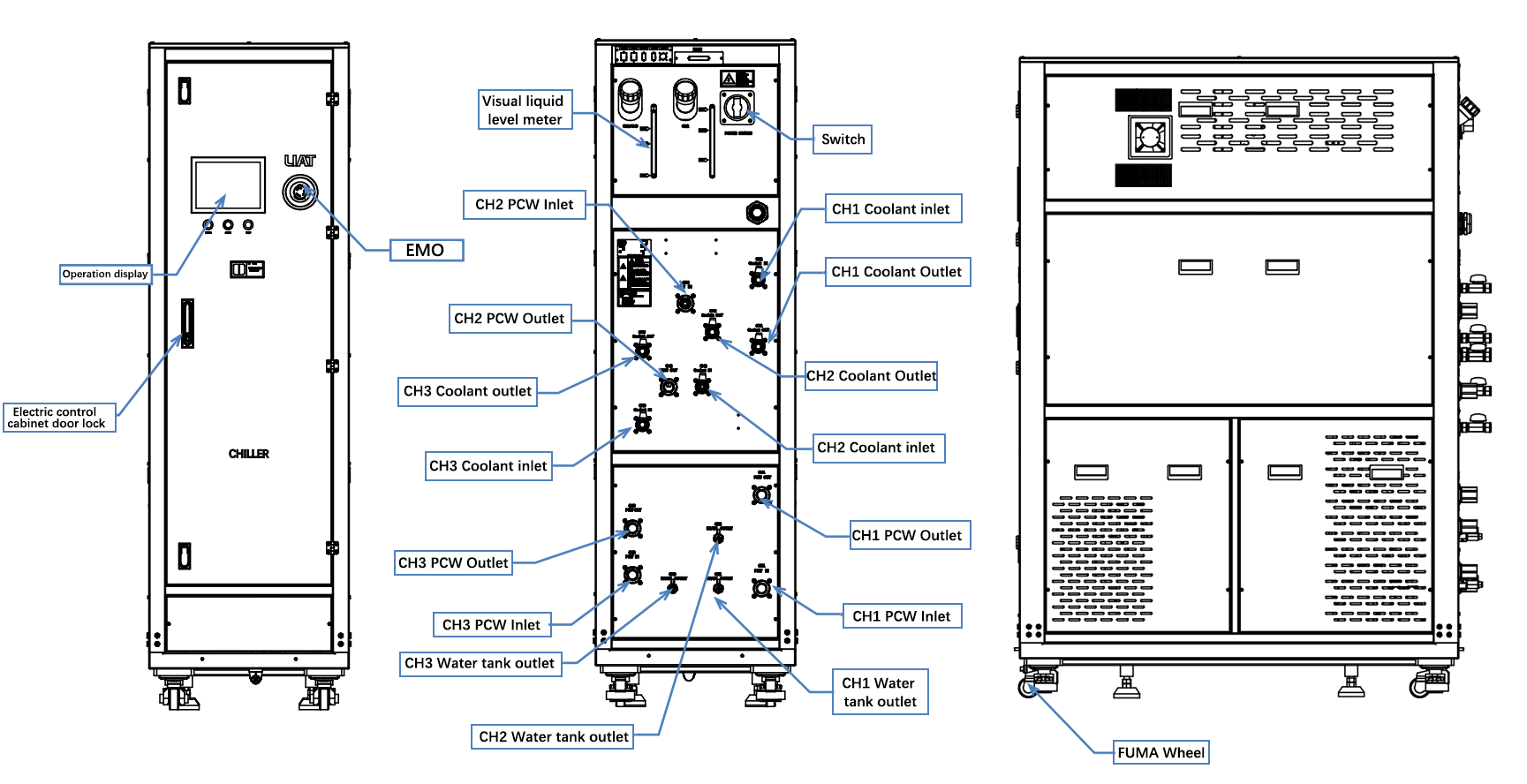

| VT410 Product Parameters | VT210-W-32 |

|

| Product Name | Chiller | |

| Product Model | VT410-W-33 | VT210-W-33 |

| Cooling Method | Water-cooling | |

| Control Mode | PID control | |

| Temperature Control Range | CH1:-45~+60℃ | CH1:+10℃~+80℃ |

| CH2:+30~+90℃ | CH2:+30℃~+90℃ |

|

| CH3:+10~+55℃ | CH3:+30℃~+90℃ | |

| Precision | ±0.1℃ | |

| Cooling capacity | CH1:6KW@-40˚C | CH1:15 KW @20°C |

| CH2:30KW@+30℃ | CH2:20 KW @+60°C |

|

| CH3:28KW@+20℃ | CH3:20 KW @+60°C | |

| Power | CH1:4KW | |

| CH2:14KW | ||

| CH3:4KW | ||

| Tank | CH1 / CH2 shared expansion tank 30L + hot water tank 25L | |

| Circulating fluid flow | CH1:17 L/min @ 0.9MPa |

25L-30L/[email protected]

|

| CH2:17 L/min @ 0.9MPa | ||

| CH3:25 L/min @ 0.76MPa | ||

| PCW traffic | CH1: 50 L/min@15~25℃@0.3MPa | |

| CH2: 20 L/min@15~25℃@0.3MPa | ||

| CH3: 50 L/min@15~25℃@0.3MPa | ||

| Temperature range | 5~35 ℃ | |

| Circulating fluid type | FC3283 | |

| Circulating liquid interface | CH1/CH2/CH3: Rc 3/4" | CH1/CH2/CH3: Rc 3/4" |

| PCW interface | CH1/CH2/CH3: Rc1" | CH1/CH2/CH3: Rc1-1/4" |

|

External dimensions (mm) |

600W*1370D*2000H | 1100W*1400D*1600H |

| Input power supply | 3Ph,380-400V,50Hz | |

| Whole Machine Power | 41.1 KW | |

| Net Weight | 600 kg | |

| Design Standards |

SEMI |

|