CO2 Chillers

Temperature Stability: ±0.1℃

Temperature Range: -20˚C~+80˚C

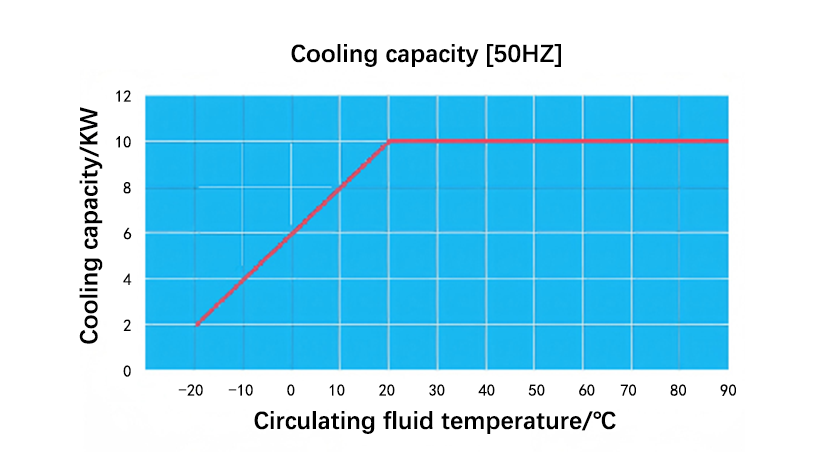

Cooling Capacity: -20℃@2 KW/20℃@10 KW

Delivering precision thermal control through compact compressor chillers for:

Semiconductor wafer fabrication & testing

New energy battery/e-drive validation

Precision equipment coolin

Test-specific air-cooling applications

- Overview

- Recommended Products

Technical Description:

Lingheng CO₂ Ultra-Clean Chiller

Utilizing natural refrigerant (GWP=1, ODP=0) to deliver ±0.1℃ precision thermal control for advanced semiconductor processes. Enables -40℃ to +100℃ wide-range operation via transcritical cycle technology, compatible with mission-critical applications:

Photolithography

Etching

Atomic Layer Deposition (ALD)

Full-sealed flow path meets Class 100 cleanroom standards, while F-gas free design mitigates carbon tax exposure — achieving both process excellence and ESG compliance.

Key Advantages:

Environmental Sustainability:

GWP=1 - Fully aligned with global climate targets, mitigating carbon tax exposure

Natural refrigerant - Eliminates fluorinated gas recovery/disposal requirements

Zero ODP - Compliant with international regulations (e.g., Kigali Amendment)

±0.1℃ precision control - Enables advanced nodes (TSMC 5nm fluorinated refrigerant phase-out compliant)

Contamination-free operation - CO₂ residue <1ppb, certified for Class 1000 cleanrooms

30% higher COP - Transcritical cycle inverter tech (verified vs. LIAT 1.0 baseline)

Safety Performance:

Non-toxic & non-flammable - Eliminates fluorinated refrigerant leakage risks

Fab risk reduction - 68% lower environmental hazard index (per SEMI S10)

Core Components & Operation:

Component |

Technology |

Compressor |

Hermetic inverter compressor with liquid slugging protection (±0.5℃ control) |

Condenser |

Stainless steel, <5% thermal loss |

Evaporator |

Titanium plate-type, 35% higher efficiency, ≤55dB noise |

Heater |

Submerged direct-heating, ±0.3℃ uniformity |

Expansion Valve |

Electronic valve with ±1℃ superheat control |

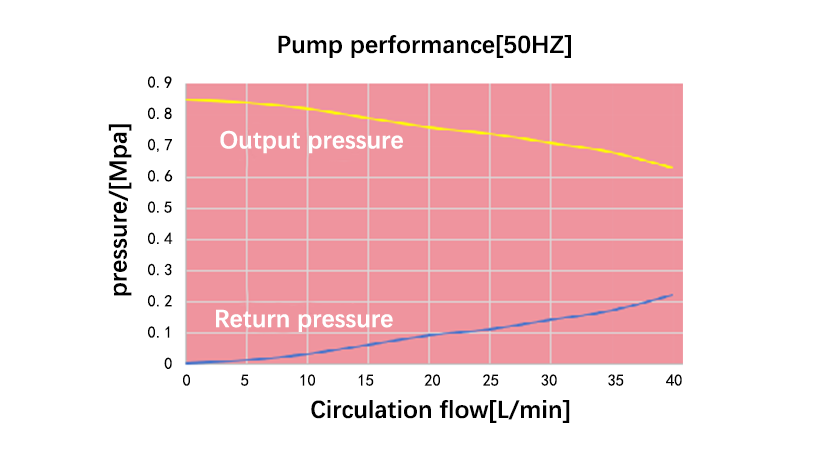

Pump |

Mag-drive pump (fluorinated fluid version), <2% flow fluctuation |

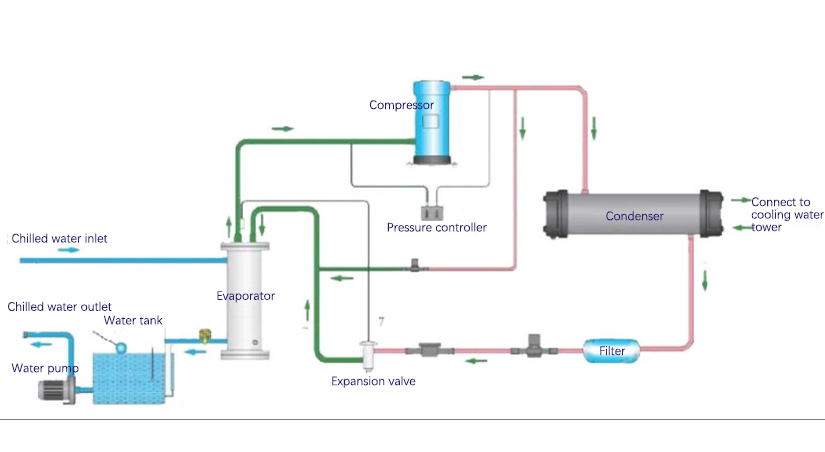

Refrigeration Principle:

1. Compression → Refrigerant pressurization

2. Condensation → Heat dissipation & liquefaction

3. EEV throttling → Low-pressure mist generation

4. Evaporation → Precision heat absorption from equipment

5. Inverter flow control → Maintains ±0.1℃ stability

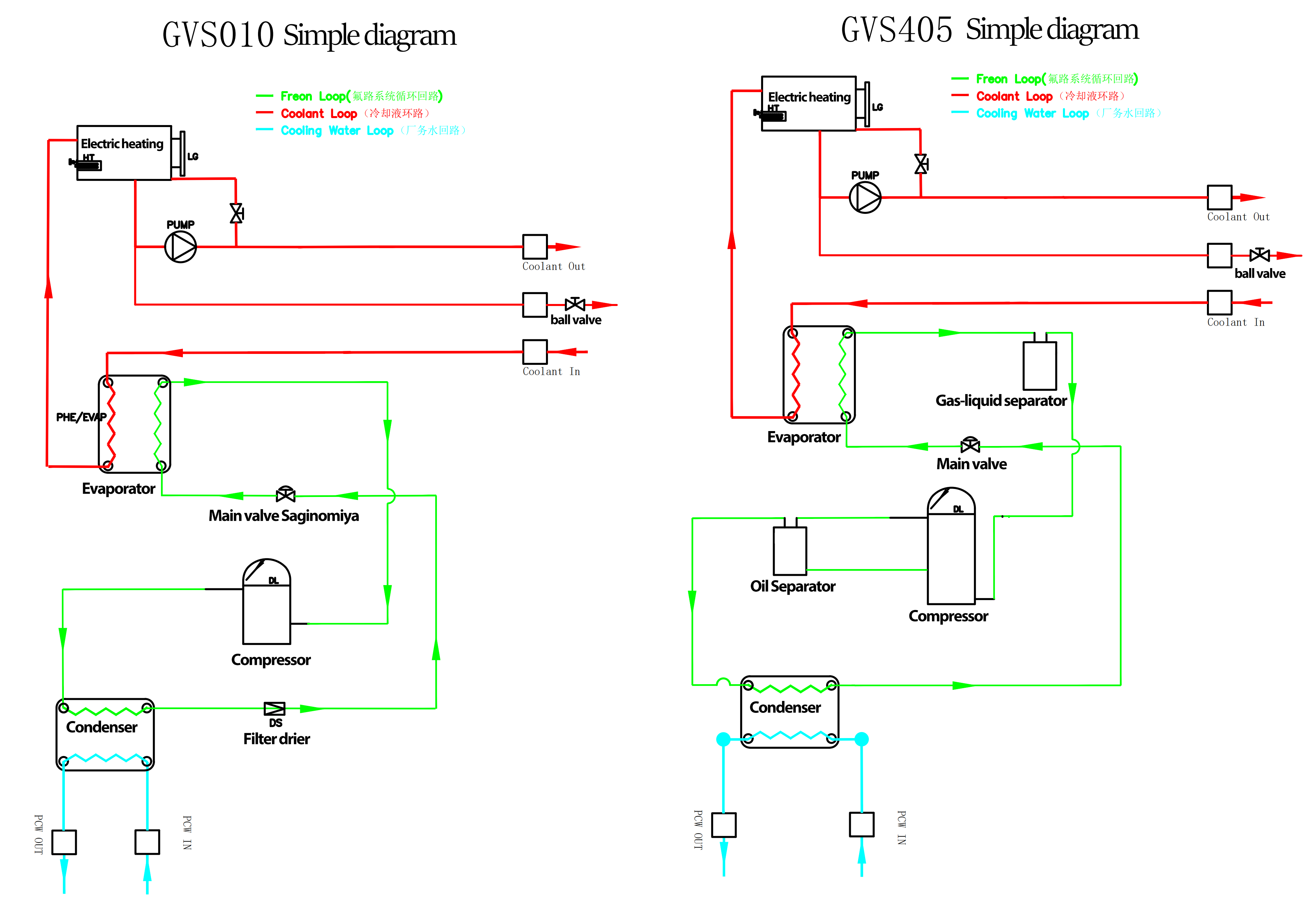

| GVS010 Product Parameters | GVS405 Product Parameters | ||

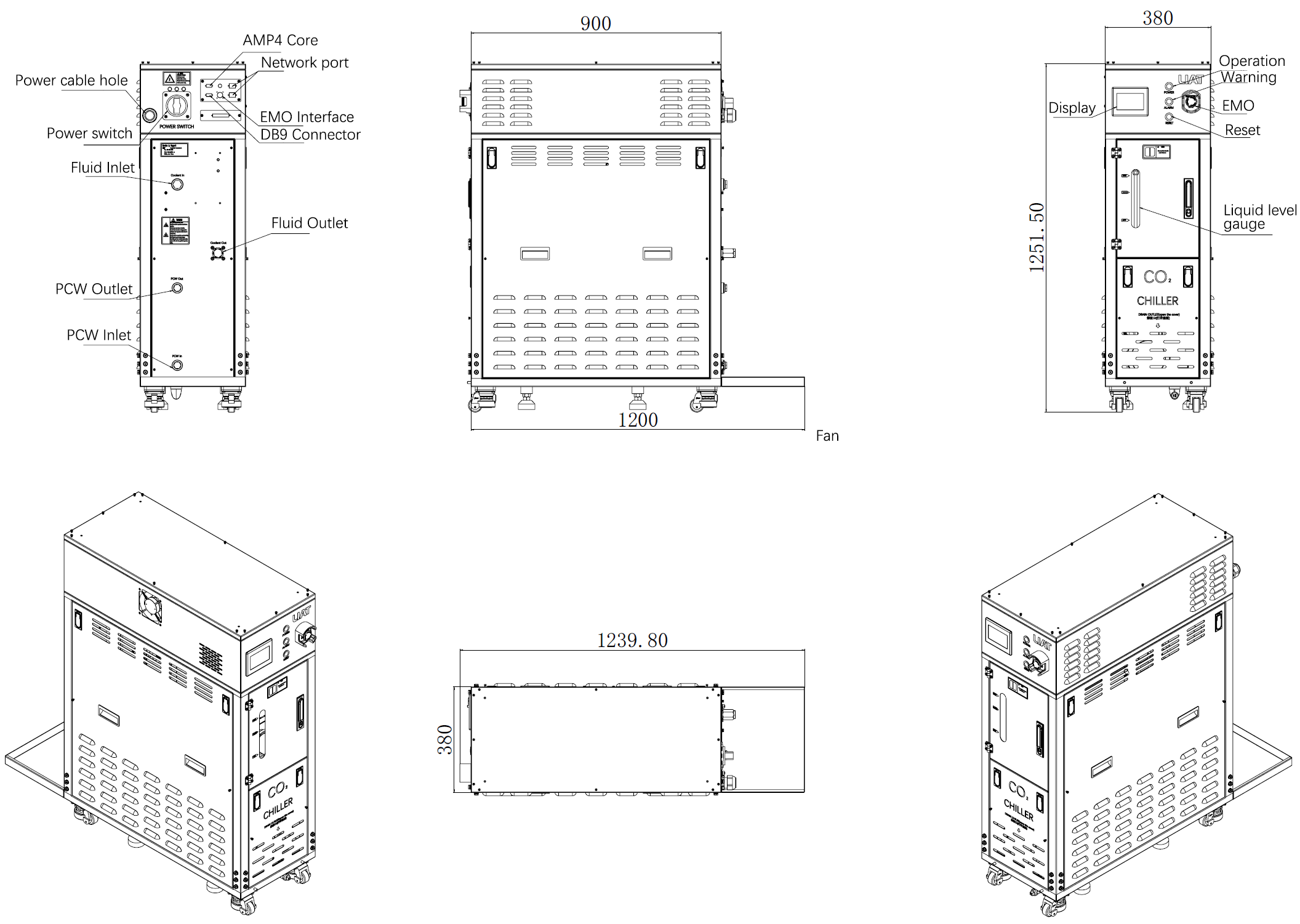

| Product Model | GVS010-W-32F | GVS405-W-32F | GVD010-W-32F |

| Cooling Method |

Water-Cooled Cooling Type |

||

| Control Mode |

Pid Control |

||

| Temperature Control Range | -20℃~+90℃ | -40℃~+90℃ | -20℃ to +90℃ |

| Precision |

±0.1℃ |

||

| Refrigeration Capacity |

-20℃@2 KW -10℃@4 KW 0℃@6 KW 20℃@10 KW 80℃@10 KW |

-40℃@4KW |

4kW@-10℃ 10 kW @+20℃ |

| Power | 3kW | 3kw | |

| Tank | 20L | 20L | |

| Circulating Liquid Flow Rate | 20L/min(0.75Mpa) | 20L/min(0.5Mpa) | 20L/min(0.7Mpa) |

| PCW Traffic | 15L/min@15~25℃ | 15 LPM @15 ~25 ℃@0.3~0.4Mpa | |

| Temperature Range | 5~35℃ | ||

| Types of Circulating Fluid | Ethylene Glycol Mixture, Pure Water,Fluorinated Solution | ||

| Refrigerant | R744(CO2) | ||

| Circulating Liquid Interface |

Rc3/4” |

||

| PCW Interface | Rc1/2” | Rc1-1/4” | Rc1/2” |

| External Dimensions(mm) | 380W*900D*1250H | 500W*1160D*1650H |

600W*900D*1300H(mm) |

| Input Power Supply | 3Ph,208-220V,50Hz | 3Ph,208-220V,50/60Hz | |

| Machine Power | 8kW | 15.4kW | |

| net Weight | 200kg | ||

| Design Standards | SEMI | SEMI | SEMI S2、 F47 |