Dual Channel Chiller

Temperature Stability: ±0.1℃

Temperature Range: -20˚C~+80˚C

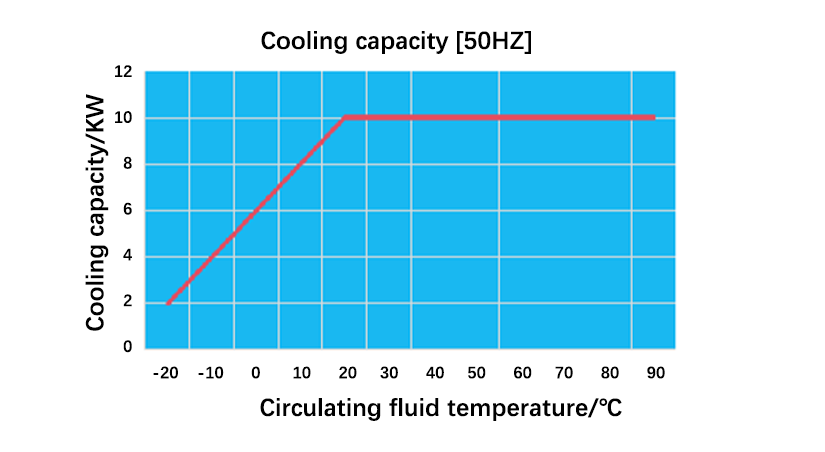

Cooling Capacity: -20℃@2 KW/20℃@10 KW

Dual-circuit precision cooling system delivering the performance of two independent chillers in a single unit. Achieves ±0.1℃ stability per circuit for critical semiconductor applications:

PVD/CVD tool temperature control

Etching process thermal management

Industry-proven compatibility with AMAT, LAM, AMEC, TEL, and other major Fab equipment.

- Overview

- Recommended Products

Technical Description:

Lingheng Dual-Circuit Chillers deliver dual independent temperature control in a single unit.

Featuring ±0.1℃ stability per circuit, these systems are engineered for:

Synchronized cooling of PVD/CVD chambers

Multi-zone thermal management in etching tools

With 40% smaller footprint and industry-proven compatibility (AMAT/LAM/TEL), they redefine space-efficient precision cooling.

Key Advantages:

Two-in-One Efficiency

» Replaces dual chillers with independent circuits

→ 40% cleaneroom space saved + 30% CAPEX reduction

Precision Dual Control

» ±0.1℃ stability per circuit (ΔT<0.2℃)

→ Ensures <3% film thickness variation in CVD/PVD

Fab-Ready Integration

» Pre-loaded AMAT/LAM/TEL protocols

→ 90% 300mm tool compatibility, 65% less downtime

Energy TwinDrive™

» 35% lower energy vs. conventional pairs

→ SEMI S23 certified, >$18k annual savings

Zero Cross-Contamination

» Customizable flow paths + laser-welded joints

→ Compatible with UPW/fluorinert/EGW

Core Components & Operation:

Component |

Technology |

Compressor |

Hermetic inverter compressor with liquid slugging protection (±0.1℃ control) |

Condenser |

Stainless steel, <5% thermal loss |

Evaporator |

Plate-type design, 35% higher efficiency, ≤55dB noise |

Heater |

Submerged direct-heating, ±0.3℃ uniformity |

Expansion Valve |

Electronic valve with ±1℃ superheat control |

Pump |

Mag-drive pump (fluorinated fluid version), <2% flow fluctuation |

Refrigeration Principle:

Adaptive PID Refrigeration Cycle:

1️⃣ Compression → Refrigerant pressurization

2️⃣ Condensation → Heat dissipation & liquefaction

3️⃣ EEV throttling → Low-pressure generation

4️⃣ Evaporation → Precision heat absorption from equipment

5️⃣ Inverter flow control → Maintains ±0.1℃ stability

| VD100 Product Parameters | |

| Product Model | VD100-W-32 |

| Cooling Method | Water-Cooling |

| Control Mode | PID Control |

| Temperature Control Range | -20℃~+80℃ |

| Precision | ±0.1℃ |

| Refrigeration Capacity |

CH1/ CH2: -20℃@2 KW - 10℃@4 KW 0℃@6 KW 20℃@10 KW 80℃@10 KW |

| Power |

CH1:3KW CH2:3KW |

| Tank |

CH1: 20 L CH2: 20 L |

| Circulating Liquid Flow Rate |

CH1:20 L/min(0.75 MPa) CH2:20 L/min(0.75 MPa) |

| PCW Traffic | CH1: 15 L/min@15~25 ℃ CH2: 15 L/min@15~25 ℃ |

| Temperature Range | 5~35℃ |

| Types of Circulating Fluid | Ethylene glycol mixture, pure water, fluorinated liquid |

| Refrigerant | R410A |

| Circulating Liquid Interface | Rc3/4“ x 2 |

| PCW Interface | Rc1/2” x 2 |

| External Dimensions(mm) | 600W*920D*1300H |

| Input Power Supply | 3Ph,208-220V,50Hz |

| Machine Power | 16kW |

| net Weight | 350kg |

| Design Standards | SEMI |