In the highly specialized realm of modern pharmaceutical manufacturing, the production of Active Pharmaceutical Ingredients (APIs) and their intermediates stands as the critical foundation determining the ultimate quality, safety, and efficacy of final drug products. This process, encompassing complex chemical synthesis, precise fermentation, and meticulous extraction, demands an environment of unwavering stability and control. At the heart of this controlled environment lies a single, non-negotiable parameter: temperature.

Even minor temperature deviations can cascade into significant challenges, directly impacting:

➡️ Reaction Kinetics and Pathways: The speed and very path of chemical reactions are intrinsically tied to temperature. Fluctuations can lead to incomplete reactions, the formation of unwanted side products, or altered molecular structures.

➡️ Product Purity and Selectivity: Consistent temperature is vital for achieving high selectivity, ensuring the desired molecule is produced with minimal impurities. This is paramount for meeting stringent regulatory standards and ensuring patient safety.

➡️ Microbial Activity and Overall Yield: In bioprocesses and fermentations, temperature controls the metabolic rate of microorganisms. Precise control maximizes the production of the target compound, directly optimizing batch yield and cost-efficiency.

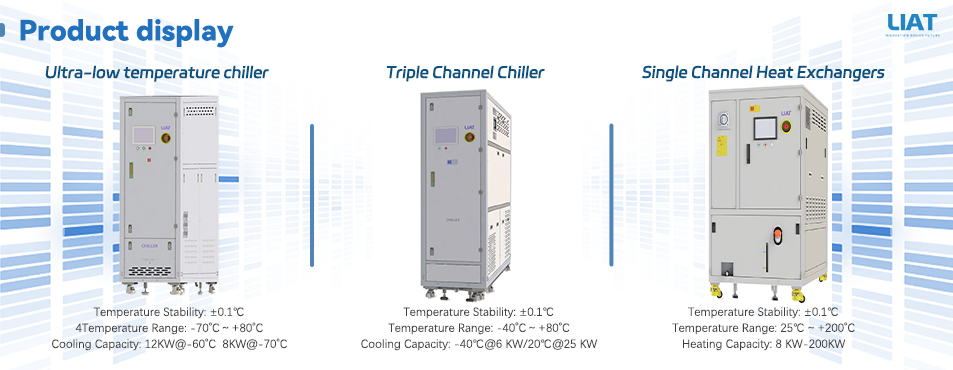

Understanding these critical dependencies, we deliver industry-leading, high-precision temperature control solutions engineered for excellence. Our integrated high and low-temperature control systems and advanced temperature-controlled reactor oil temperature controllers are at the forefront of this mission.

By integrating sophisticated PID temperature control algorithms and robust engineering, our systems achieve and maintain an exceptional temperature stability of ±0.1°C. This unparalleled precision ensures that every stage of your operation—from initial R&D and process development to critical scale-up and full-scale production—operates consistently within the optimal and validated process window.

Key Benefits of Our Technology:

Enhanced Product Quality: Reproducible results batch after batch, with higher purity and fewer impurities.

Increased Process Efficiency: Maximized yield and optimized reaction times through flawless thermal management.

Reduced Costs: Minimized batch failures, reworks, and raw material waste.

Accelerated Scale-up: Seamless technology transfer from laboratory to production, mitigating scale-up risks associated with temperature sensitivity.

We firmly believe that excellent pharmaceuticals begin with excellent raw materials, and excellent raw materials are born from exceptionally precise manufacturing conditions. Let us become your reliable partner in production.

Embrace the standard of ±0.1°C. Contact us today to discover how our precision temperature control solutions can safeguard your API and intermediate processes, ensuring quality from the very foundation.