Heating Jacket System

Temperature Stability: ±0.5℃

This product has the following materials to choose from according to actual needs:

Silicone Foam Materical

Ful PTFE Material

PTFE Coating Material

Expanded PTFE Material

- Overview

- Recommended Products

Technical Description:

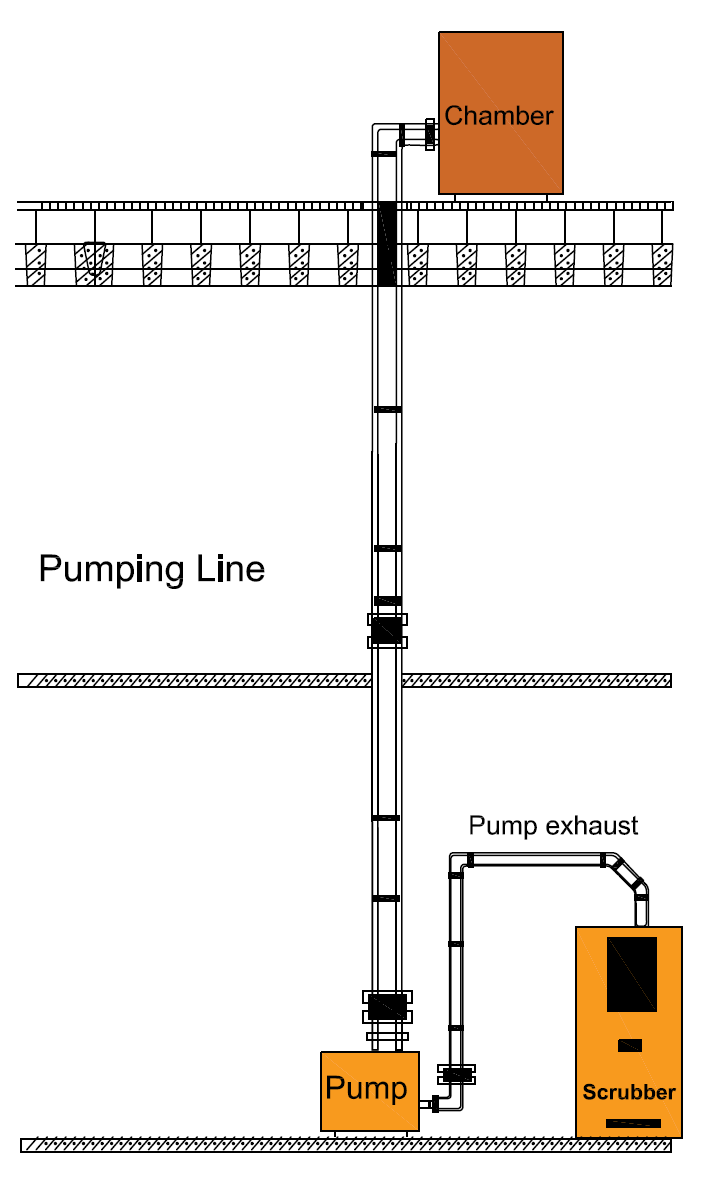

The Heating Jacket system maintains precise temperatures in vacuum/gas delivery

lines across advanced manufacturing processes. Custom-engineered for industry-specific

requirements, it prevents incomplete reactant condensation and byproduct deposition

on inner pipe walls - critical for avoiding flow obstruction and exhaust efficiency

degradation in semiconductor vacuum/exhaust systems. Comprising three core components:

Heating Jackets (trace-specific designs)

PID Controllers (±0.5℃ stability)

HMI Control Cabinets

this solution enables real-time pipeline monitoring and thermal management for stainless steel gas lines.

Heating Jacket Applications:

1. Gas Delivery Lines

Hazardous Process Gases:

Boron Trichloride (BCl₃), Chlorine Trifluoride (ClF₃), Tetraethyl Orthosilicate (TEOS)

Dichlorosilane (DCS/SiH₂Cl₂), Tungsten Hexafluoride (WF₆)

Process Validation: Gas line heating for dew point control and condensation prevention

2. CVD Processes

Low-Pressure Chemical Vapor Deposition (LPCVD)

Plasma-Enhanced CVD (PECVD)

Function: Precursor vapor temperature stabilization (±1℃)

3. Metal Etching

Plasma Etching Systems:

Aluminum Etching (Cl₂/BCl₃ chemistries)

Tungsten Etching (SF₆/WF₆ mixtures)

Function: Maintain gas reactivity consistency

Heating Jacket Advantages:

Advantage category |

Technical Characteristics |

Precision Control |

±0.5℃ stability via PID controllers (ISO 15805 certified) |

Safety Assurance |

Dual safety interlocks: |

Eco-Insulation |

PFAS-free insulation layer: |

|

Real-time current monitoring: |

PID temperature controllers

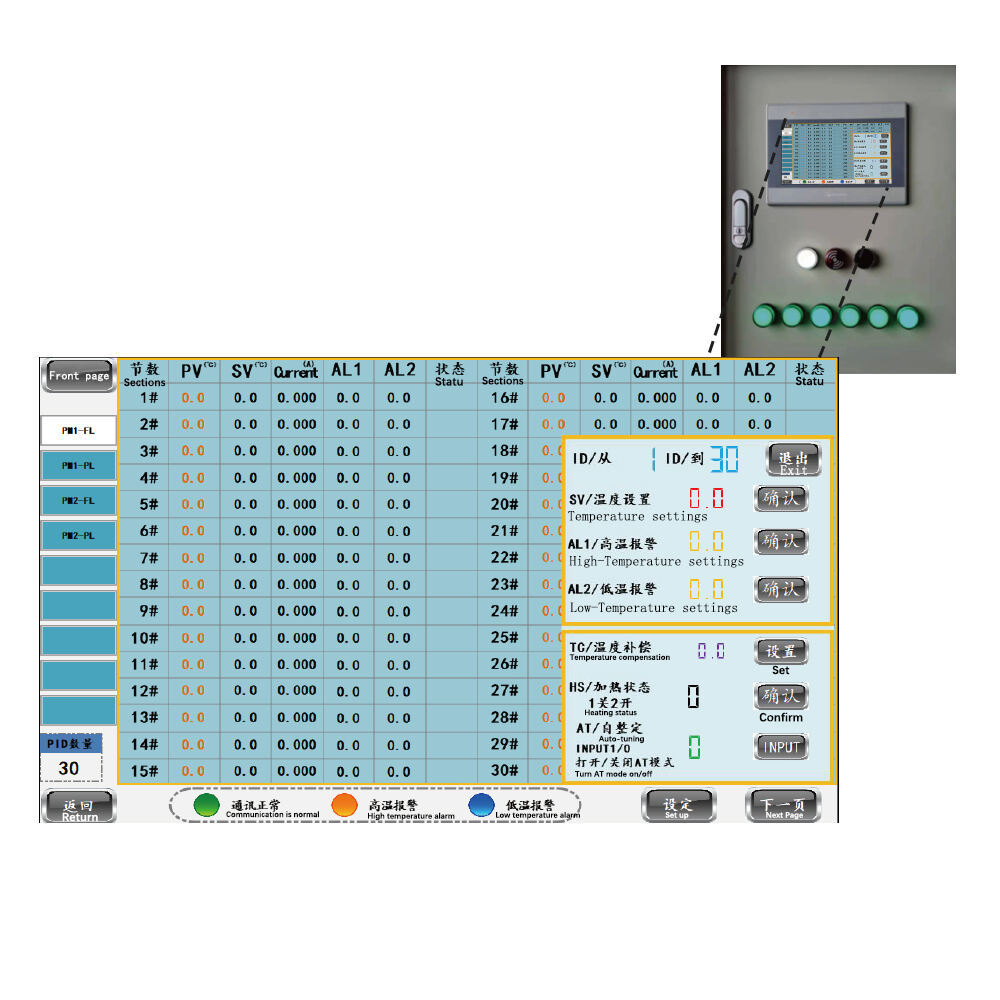

The Heating Jacket system employs PID temperature controllers for precision thermal regulation, with each controller operating on a dedicated RS485 bus segment featuring unique network addressing. These PID units function both as standalone control modules and as integrated nodes within a distributed network architecture. Utilizing Modbus RTU protocol via RS485 interfaces, all controllers communicate bidirectionally with the central HMI control cabinet to enable synchronized multi-zone temperature management and real-time data aggregation without requiring a central PLC.

HMI control panel

The installation of blanketed heating jackets and PID temperature controllers on vacuum or gas pipelines is relatively decentralized, making it impossible to effectively monitor the real-time temperatures and operational status of all heating jackets simultaneously. To enable real-time monitoring of all heating jacket conditions, we have implemented an HMI control panel that consolidates all heating jackets into a unified platform, achieving centralized control and communication management.

Centralized Monitoring System

All interfaces – including monitoring screens, real-time alarm displays, historical alarm logs, event history records, trend analysis charts, and report forms – can be configured on the host system (using SCADA platforms such as InTouch or iFix) for comprehensive monitoring of the Heating Jacket system.

System Advantages:

• Enhanced Management Efficiency - Improves overall operational performance

• Simplified Maintenance - Reduces operational and maintenance complexity

• Cost Optimization - Lowers installation, operation, and expansion expenses

• Cross-Device Monitoring - Enables mutual monitoring between multiple computers

• Resource Sharing - Facilitates centralized disk resource utilization

• Redundant Backup - Provides mutual backup functionality

• Multi-Channel Alarm Notification - Supports SMS/call alerts and email notifications

• Comprehensive Data Analysis - Allows historical data queries and graphical trend visualization

• Automated Reporting - Generates system reports automatically

• Network Management - Enables centralized monitoring system administration

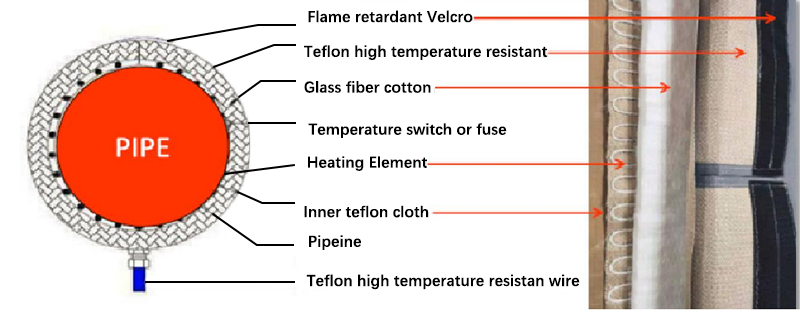

| Inner Cloth | PTFE Teflon cloth |

| Heating Element | PTFE nickel chromium electric heating element |

| Insulation | High-capacity heavy glass fiber felt |

| Outer Fabric Material | PTFE Teflon cloth |

| Fixed Buckle | Flame retardant and temperature resistant Velcro |