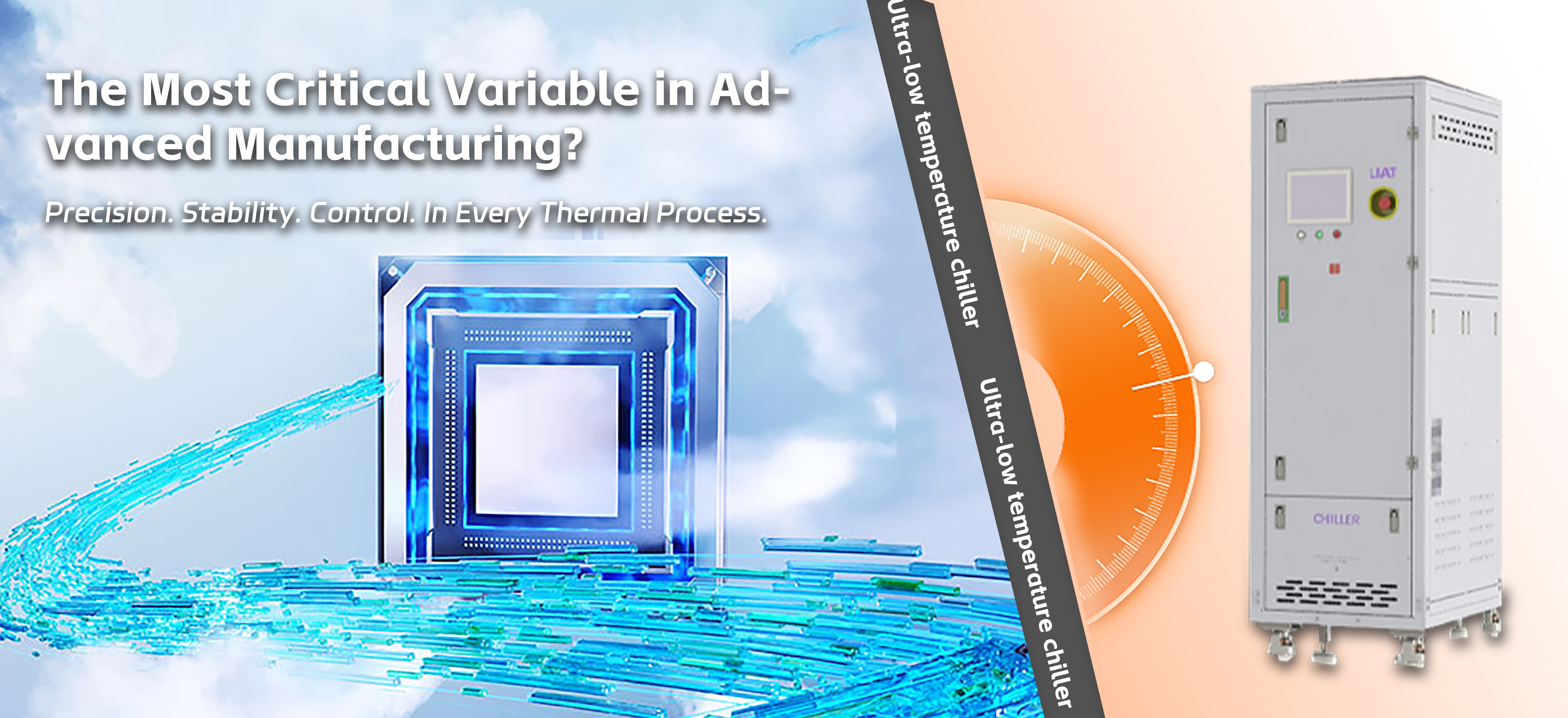

In today's industrial landscape, temperature has evolved from a simple parameter into one of the most critical factors shaping product quality, R&D outcomes, and manufacturing efficiency. From the lab to full-scale production, precise thermal management ensures not only performance but also repeatability and safety.

For R&D in New Materials:

The development of high-performance structural or specialized functional materials relies heavily on controlled thermodynamic environments. Even minor temperature variations can alter microstructural formation—impacting crystallinity, phase distribution, and interfacial properties. Consistent and precise thermal control is therefore essential to achieve target characteristics such as strength, thermal resistance, or conductivity, and to maintain batch-to-batch uniformity.

For Specialty Gas Production:

In processes such as purification and liquefaction of oxygen, nitrogen, argon, and other high-purity gases, temperature accuracy becomes a decisive factor in product purity, yield, and operational safety. A slight deviation can compromise separation efficiency, allow impurity ingress, or even pose operational risks. Reliable thermal management ensures process stability and safeguards both output quality and personnel.

We recognize that robust temperature control solutions form the foundation of a seamless innovation chain. By integrating precision into every step, we help secure the performance and reliability of your next-generation products.

We invite you to share your specific challenges and insights regarding temperature control in your field. Let’s start a conversation—and explore how tailored thermal solutions can elevate your processes.