From March 26th to 28th, 2025, SEMICON China, the annual trendsetter for the global semiconductor industry, was grandly held at the Shanghai New International Expo Centre. This grand event, covering 100,000 square meters and bringing together 1,400 exhibitors and 50,000 professional visitors, was characterized by its "internationalization and full industry chain coverage," and depicted the future landscape of the semiconductor industry through cutting-edge technology demonstrations and in-depth industry dialogues. The exhibition was full of highlights, with a constant stream of new technologies and products, injecting new vitality into the industry's development. As a leading enterprise in the R&D and manufacturing of precision temperature control equipment in the domestic semiconductor industry, Shanghai Lingheng Industrial Automation Co., Ltd. (hereinafter referred to as "Lingheng Industrial") attracted widespread attention at the exhibition for its outstanding performance and innovative achievements in the field of semiconductor manufacturing temperature control.

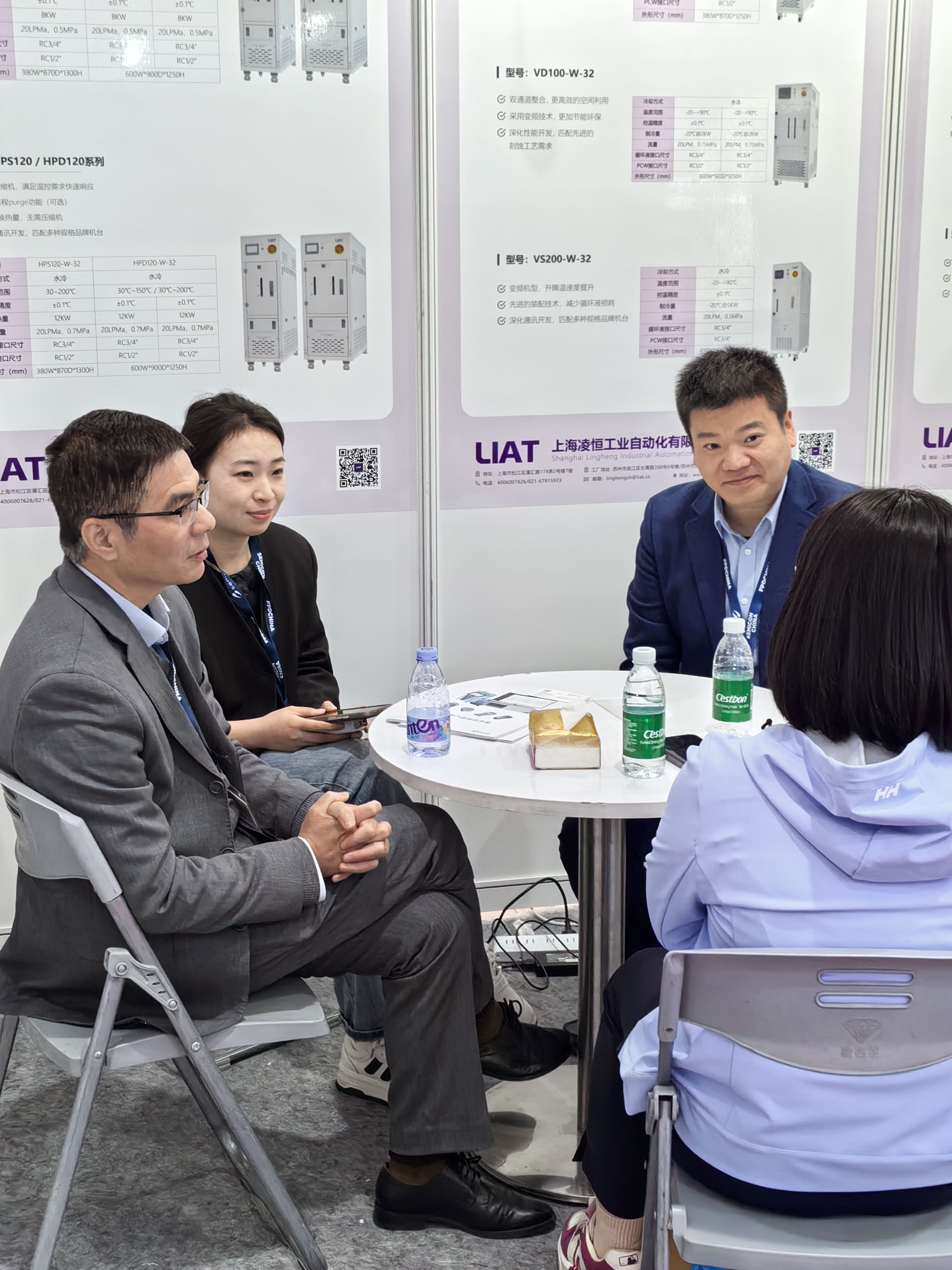

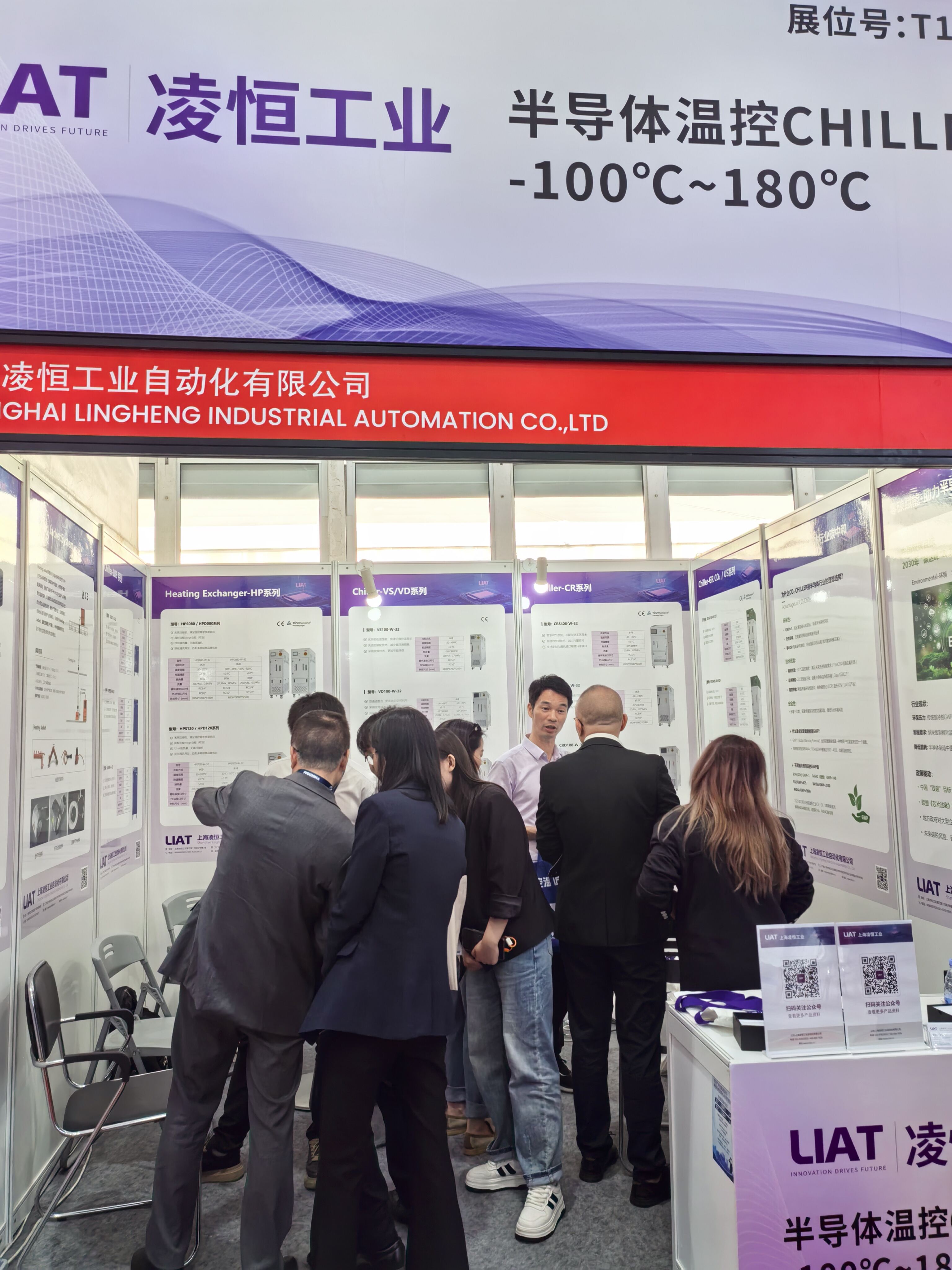

As a key player in the semiconductor industry, Lingheng Industrial has been committed to providing high and low temperature precision control solutions for semiconductor manufacturing and related fields. It has extensive experience in the research, development, production and installation of temperature control equipment for electric heating, low temperature cooling and ultra-low temperature conditions. At this exhibition, the company showcased its latest low-carbon and environmentally friendly CO2Chiller series products and mature Heating Jacket System products to the audience.

The successful debut exhibition is not the end. Lingheng Industrial will continue to deepen its involvement in the semiconductor temperature control field and looks forward to exploring new frontiers of intelligent manufacturing with you!

Exhibited Products

Energy-saving and environmentally friendly, stable and reliable, rapid response.

As a crucial component of temperature control systems in the semiconductor industry, the quality of the chiller directly impacts the temperature stability during semiconductor wafer manufacturing. Since its founding in 2013, Lingheng Industrial has continuously innovated, focusing on R&D and quality control. Its Chiller series products feature convenient setup, rapid response, high efficiency, energy saving, and precise temperature control, truly achieving low-energy consumption and high-stability cooling effects, empowering semiconductor wafer manufacturing.

Heating Jacket System

All-PTFE Material, High-Efficiency Heating

The Heating Jacket utilizes high-quality heating elements and a high-precision temperature control system, enabling rapid heating and efficient temperature control. Through continuous optimization of the heating process and the use of all-PTFE material, the overall system stability is significantly improved.

What is a Heating Jacket System?

A Heating Jacket System is used to maintain the temperature in vacuum and gas pipelines used in various technological production processes. It is custom-made to meet specific customer requirements.

Currently, it is widely used for temperature maintenance in semiconductor vacuum or exhaust stainless steel tubes to prevent unreacted media from forming byproducts that condense on the inner wall of the tube due to low internal temperatures, causing blockages or other problems that reduce exhaust efficiency.

The system consists of a Heating Jacket, a temperature controller, and an HMI control box, used for real-time monitoring of pipeline conditions and heating pipelines.

Typical Applications

Gas delivery piping (boron trichloride (BCl3), chlorine trifluoride (ClF3), tetraethyl orthosilicate (TEOS), dichlorosilane DCS (SiH2Cl2), tungsten hexafluoride (WF6), process gas pipeline qualification; CVD and metal etching (low-pressure chemical vapor deposition, plasma-enhanced chemical vapor deposition); plasma etching (aluminum etching, tungsten etching).