Single Channel Chillers

Temperature Stability: ±0.1℃

Temperature Range: -40˚C~+80˚C

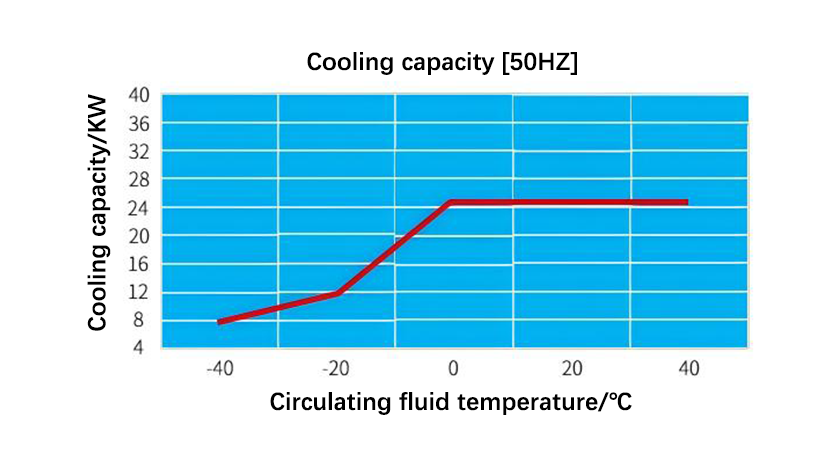

Cooling Capacity: -40℃@6 KW/20℃@25 KW

Featuring inverter-based temperature control, this system enhances energy efficiency while reducing power consumption. Delivers ±0.1℃ stability for precision-critical applications including:

Semiconductor etching tools & CMP (Chemical Mechanical Polishing)

Laboratory instruments & high-precision test equipment

Aesthetic medical devices & solid-state lasers

Mold temperature control systems

- Overview

- Recommended Products

Technical Description:

Lingheng Single Channel Chillers deliver targeted thermal management with integrated compact design.

Engineered for precision cooling of standalone equipment, our units feature ±0.1℃ PID control and

inverter compressor technology for critical applications including:

Semiconductor metrology tools

Laser processing systems

Medical analyzers

Test bench setups

Isolated fluid circuit prevents cross-contamination, while PCW-free construction reduces installation costs by 30%.

Key Advantages:

Cryogenic Excellence: Operates at -40℃ with <3min temperature transition

Zero-Loss Circulation: Laser-welded piping with <0.1% annual fluid loss

Inverter Efficiency: 35% energy savings vs. fixed-speed models (SEMI S23 certified)

Dynamic Ramp Performance: Achieves ±5℃/min temperature change rates

Multi-Protocol Integration: SECS/GEM & OPC-UA ready for ASML/TEL/LAM tool integration

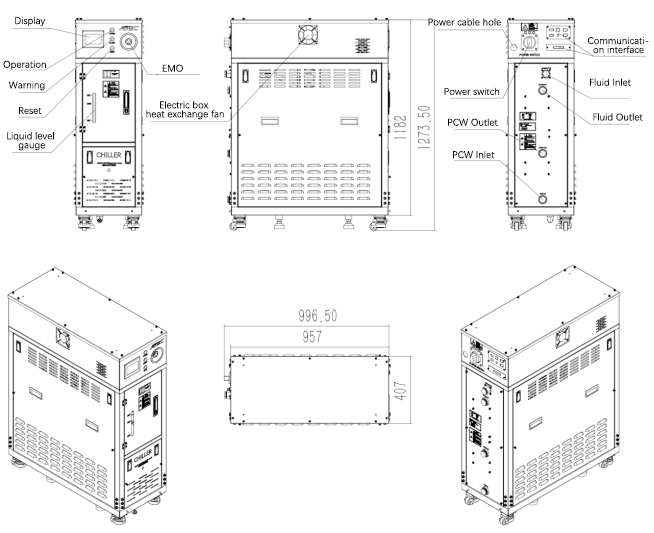

Core Components & Operation

Component |

Technology |

Compressor |

Hermetic inverter compressor with liquid slugging protection (±0.1℃ control) |

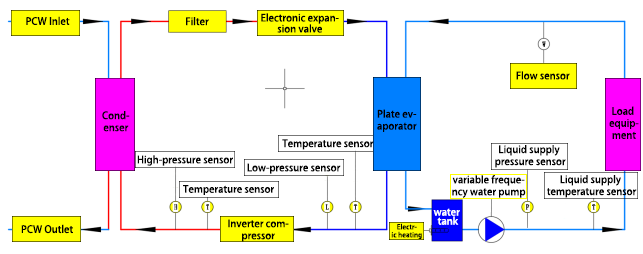

Condenser |

Stainless steel, <5% thermal loss |

Evaporator |

Plate-type design, 35% higher efficiency, ≤55dB noise |

Heater |

Submerged direct-heating, ±0.3℃ uniformity |

Expansion Valve |

Electronic valve with ±1℃ superheat control |

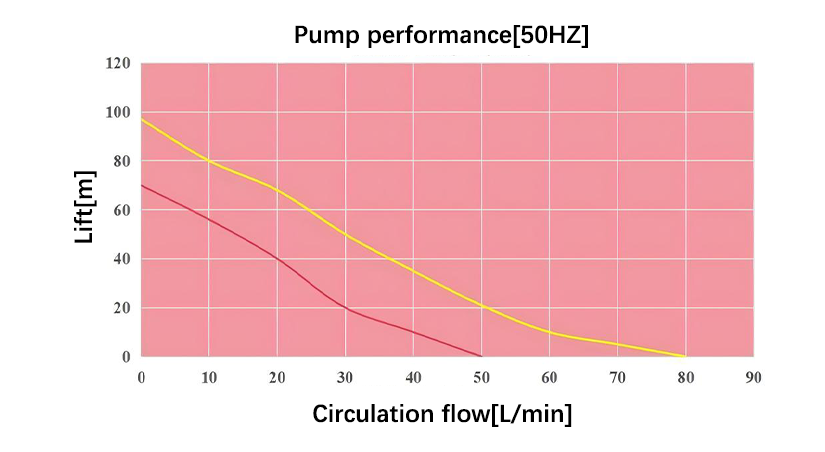

Pump |

Mag-drive pump (fluorinated fluid version), <2% flow fluctuation |

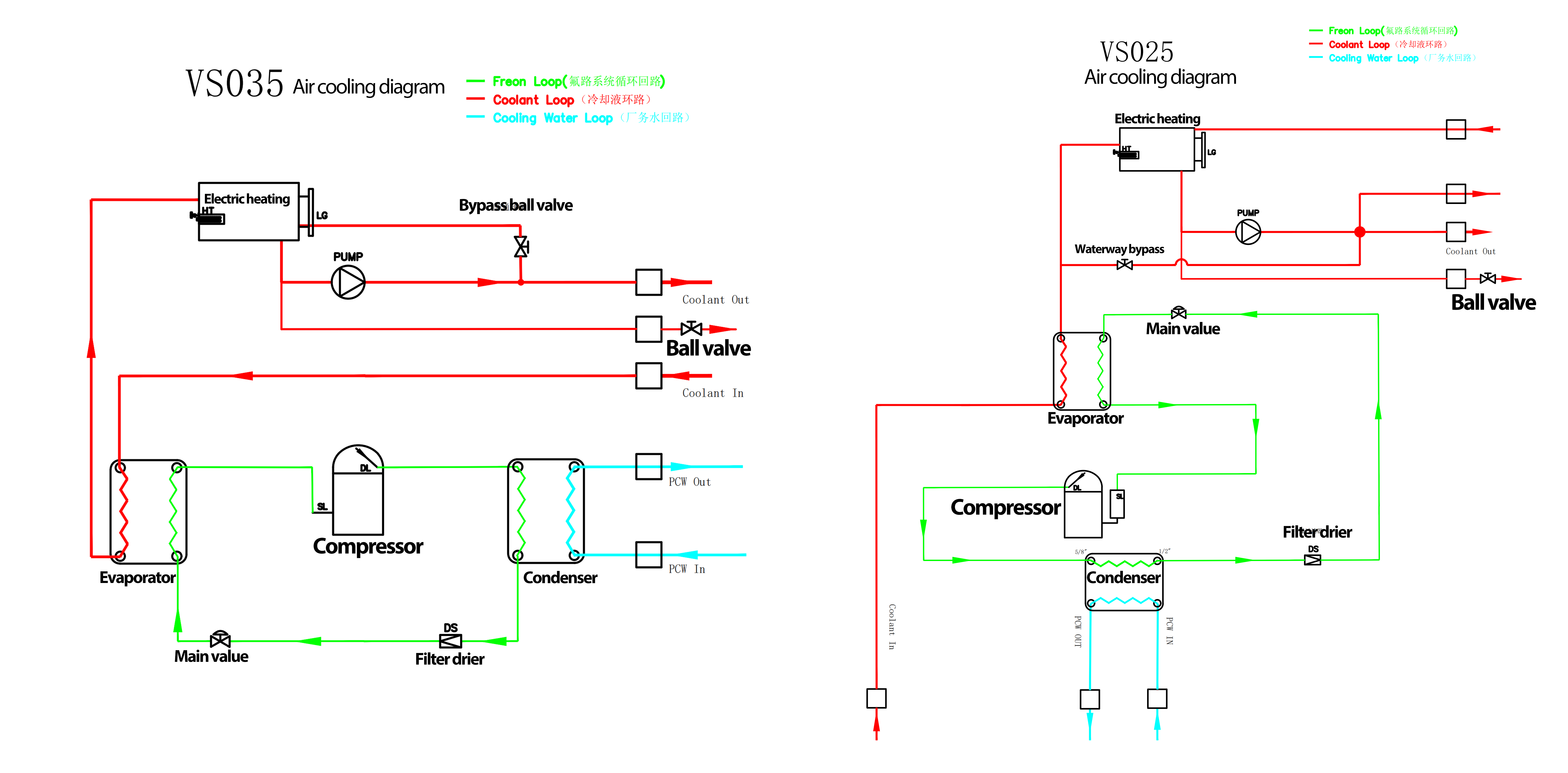

Refrigeration Principle

Adaptive PID Refrigeration Cycle:

1️⃣ Compression → Refrigerant pressurization

2️⃣ Condensation → Heat dissipation & liquefaction

3️⃣ EEV throttling → Low-pressure generation

4️⃣ Evaporation → Precision heat absorption from equipment

5️⃣ Inverter flow control → Maintains ±0.1℃ stability

| VS100/407/020 Product Parameters | |||

| Product Model | VS100-W-32 | VS020-W-32 | VS407-W-33 |

| Cooling Method | Water-Cooling | ||

| Control Mode | PID Control | ||

| Temperature Control Range | -20℃~+80℃ | -40℃~+80℃ | |

| Precision | ±0.1℃ | ||

| Refrigeration Capacity |

-20℃@2 KW -10℃@4 KW 0℃@6 KW 20℃@10 KW 80℃@10 KW |

-20℃@5 KW -10℃@10 KW 0℃@15 KW 20℃@25 KW 40℃@25 KW |

-40℃@6 KW -20℃@12 KW 0℃@25 KW 20℃@25 KW 40℃ @25 KW |

| Power | 3kW | ||

| Tank | 20L | 25L | |

| Circulating Liquid Flow Rate | 20L/min(0.75Mpa) | 20L/min(0.7Mpa) | |

| PCW Traffic | 15L/min@15~25℃ | 30L/min@15~25℃ | 50 L/min@15~25℃ |

| Temperature Range | 5~35℃ | ||

| Types of Circulating Fluid | Ethylene glycol mixture, pure water, fluorinated liquid | Clear water, Ethylene glycol mixture, Pure water, Fluorinated solution | Ethylene glycol mixture, fluorinated liquid |

| Refrigerant | R410A | / | / |

| Circulating Liquid Interface | Rc3/4“ | ||

| PCW Interface | Rc1/2” | Rc3/4" | Rc1-1/4" |

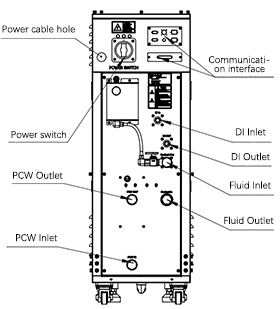

| External Dimensions(mm) | 380W*900D*1300H | 420W*900D*1250H | 500W*1150D*1500H |

| Input Power Supply | 3Ph,208-220V,50Hz | 3Ph,208-220V,50Hz | 3Ph,380-400V,50Hz |

| Machine Power | 8KW | 9.7kW | 14kW |

| net Weight | 200kg | 210kg | 360kg |

| Design Standards | SEMI | ||