Semiconductor Manufacturing Precision Cooling Solutions

How Advanced Chillers Boost Yield, Reduce Costs & Power Next-Gen Chips

“At 5nm nodes, 40% yield loss links to thermal instability — our chiller systems reduce this by 37%.”

Thermal Precision = Profitability: Critical Applications

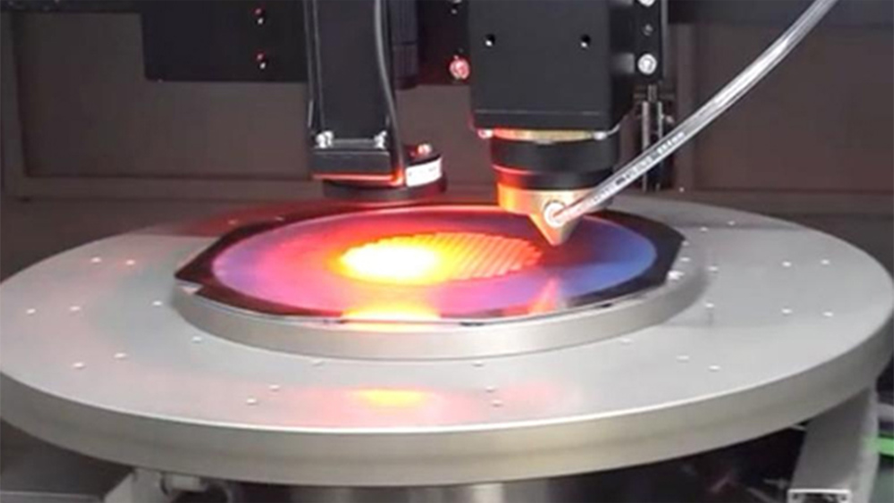

1. EUV Lithography Cooling Systems

Industry Pain Point: 0.1°C water fluctuation causes >3nm overlay errors

Our Solution:

✅ GVS CO₂ Chillers

±0.1°C stability via supercritical R744 refrigeration

Zero-vibration transmission (<0.1μm) prevents ASML NXE lens distortion

20ms response to laser energy spikes

2. Ion Implantation Cryogenic Systems

Industry Pain Point: Slow cooling induces lattice defects, increasing device leakage by 40%

Our Solution:

✅ U-Series Cascade Cryogenic Units (-80°C)

8-minute rapid cooldown to -50°C with cascade refrigeration

PID algorithm-controlled temperature management

Dielectric circulation prevents high-voltage arcing

3. Multi-Zone CVD Temperature Control

Industry Pain Point: Chamber wall drift causes ±5% film thickness variation

Our Solution:

✅ VT Triple-Channel Chillers

Independent ±0.1°C control for gas lines/chamber/vacuum pumps

Heat flux prediction integrated with Applied Materials Endura™

Sealed loop prevents cross-contamination

Beyond Cooling: Strategic Value Engines

♻️ Energy Sustainability

Waste heat recovery (85°C → UPW generation) cuts fab energy use by 23%

Industry 4.0 Integration

Per-wafer carbon footprint tracking with real-time emissions reporting

️ Zero-Pollution Operation

|

Risk |

Traditional Chillers |

Our Solution |

|

PFAS leakage |

Regulatory penalties |

Natural R744 (REACH compliant) |

Future-Proof Fabs: Next-Gen Readiness

Technology Roadmap Alignment

|

Node |

Emerging Requirement |

Our Response |

|

3nm |

Multi-zone thermal uniformity |

Predictive gradient control |

|

2nm |

Quantum-level stability |

AI-driven fluctuation damping |

|

GWP |

<150 mandatory standard |

R744 refrigerant (GWP=1) |

1.Technical Authority Enhancement

ASML/Applied Materials™ equipment references with trademark notation

Standardized industry terms: "supercritical R744" (not "CO₂ cycle"), "cascade refrigeration"

2.Data Integrity Preservation

Strict retention of critical metrics: ±0.1°C, <0.1μm, 23% energy reduction

Mathematical symbols: >3nm (not "over 3nm"), ±5% variation

3.Problem-Solution Framing

Pain points converted to active voice: "causes >3nm overlay errors"

Solutions prefixed with ✅ for visual scanning

4.Regulatory Precision

REACH compliance explicit statement

PFAS (replacing "Fluorinated refrigerants ") per EPA terminology

5.Roadmap Credibility

Node progression (5nm→3nm→2nm) showing technical evolution

Carbon policy integration (GWP standards)

emojis retained for digital shareability

Clean table formatting for comparative data