Our Heating Jacket System delivers precise and stable temperature control (±0.5℃) for vacuum and gas delivery lines in semiconductor, CVD, and etching processes. Designed to prevent condensation, deposition, and flow obstruction, this system ensures consistent process performance and extended equipment life.

Available in multiple material options to suit your application needs:

Silicone Foam

Full PTFE

PTFE Coating

Expanded PTFE

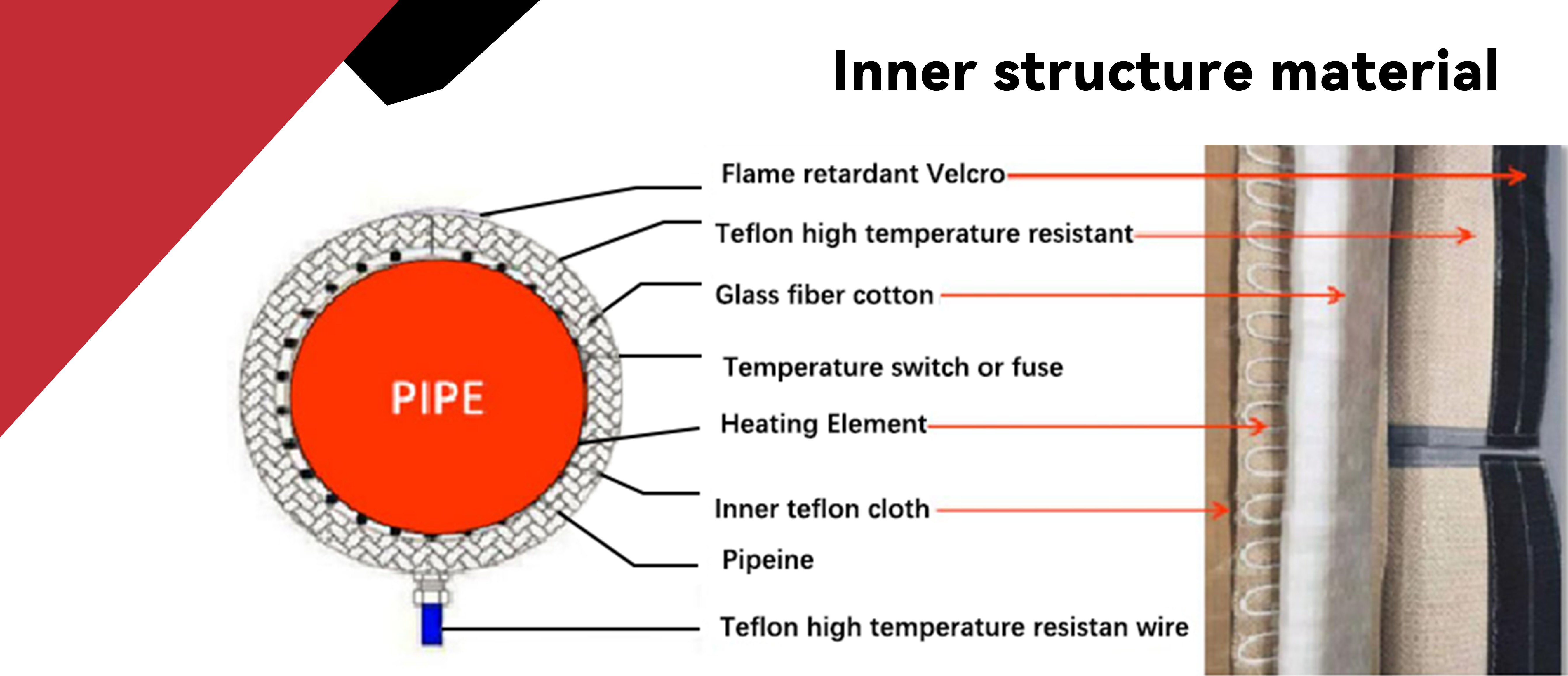

The system integrates three core components to provide reliable and intelligent thermal management:

Heating Jackets – Custom-engineered for specific pipe layouts and trace requirements.

PID Controllers – Ensure temperature stability within ±0.5℃, with dedicated RS485 communication and Modbus RTU protocol.

HMI Control Cabinets – Centralize monitoring and control of multiple heating zones in real time.

Gas Delivery Lines – Maintains dew point control for hazardous gases such as BCl₃, ClF₃, TEOS, DCS, and WF₆.

CVD Processes – Stabilizes precursor vapor temperature in LPCVD and PECVD systems (±1℃).

Metal Etching – Ensures consistent gas reactivity in plasma etching for aluminum, tungsten, and other materials.

| Feature | Benefit |

|---|---|

| Precision Control | ±0.5℃ stability with ISO 15805 certified PID controllers. |

| Dual Safety System | Built-in KSD30 thermostat and IEC 60691 compliant thermal fuse. |

| Eco-Friendly Insulation | PFAS-free, <5% thermal loss, housed in sleek stainless steel. |

| Smart Monitoring | Real-time current per zone, MODBUS-TCP integration with HMI/SCADA. |

| Centralized Management | Compatible with InTouch, iFix, and other SCADA platforms for full system oversight. |

Our HMI Control Cabinet consolidates all heating jackets into one interface, enabling:

Real-time temperature and status monitoring

Historical data logging and trend analysis

Automated reporting and alarm notifications (SMS, email, call)

Multi-computer access and mutual backup

Reduces maintenance complexity and operational costs

Supports scalable expansion and network management

Enhances process repeatability and yield in critical applications

Compliant with international standards for safety and performance

To learn how our Heating Jacket System can optimize your process thermal management, contact our engineering team for a customized solution.